The machine consists of two parts: stainless steel gear and toothed screw shaft. When working, citrus fruits are mixed along the tooth axis under the advancement of the screw shaft. Moving and tumbling, the stainless steel teeth pierce the oil cell, and the oil is simultaneously washed away by the high-pressure water, and enters the post-separation process. It is widely used in oil extraction conditions of large citrus processing plants.

1. Overview

1. The oil grinder is orange. Under the action of stainless steel licker roller and hollow spiral, it moves forward and rolls, and the stainless steel needle pierces at the same time. The oil cells cause the oil in the orange peel to flow out, and the oil is washed away under the action of high-pressure spray water, so as to achieve the oil removal effect. It is widely used in oil grinding conditions in large citrus and orange processing plants.

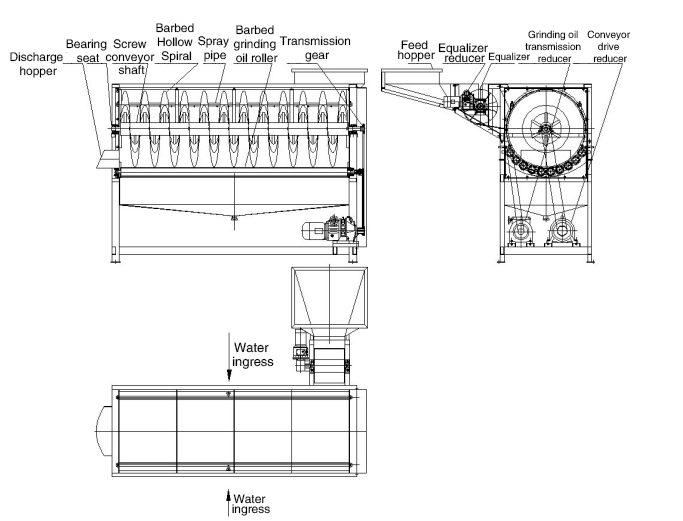

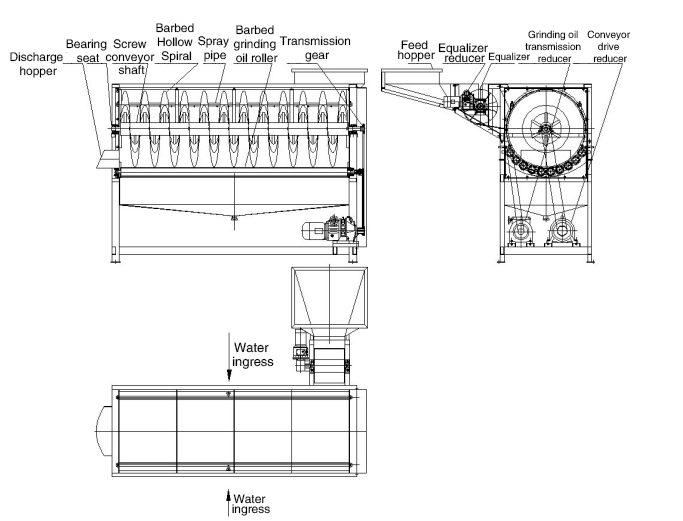

2, Structural features and working principle

The oil grinder consists of a barbed hollow screw, a screw conveyor shaft, a barbed oil grinding roller, a bearing seat, a frame, an equalizer, an equalizer reducer, an oil grinding transmission reducer, a conveying transmission reducer, a feeding hopper, and an outlet. The hopper and the oil collecting hopper are composed of components. When the orange enters the hopper, it evenly enters the oil silo under the action of the claws, and rolls and rubs the orange under the action of several barbed oil sticks. The oil cells on the surface, under the action of the barbed hollow spiral, are output to the end of the discharge port. The machine is equipped with a spray pipe obliquely above the hollow spiral. After the water sprayed from the spray pipe washes away the oil on the orange, it can reduce the viscosity between the orange and the orange, which is convenient for the orange to roll. The oil can flow smoothly into the oil collecting hopper.

3, Installation, commissioning, operation and maintenance

1. The machine must be installed horizontally and fixed with anchor screws.

2. Tighten all bolts on the whole machine. Manual idling is to turn the claws to confirm that it is flexible and free of foreign objects.

3. All lubrication parts are required to be well lubricated, and lubricating oil with the specified label is added.

4. Clean the inside and outside of the whole machine to keep it clean.

5. Connect the water inlet of the sprinkler pipe and install a control valve at the water inlet. Install a control valve at the oil outlet.

6. After the above conditions are confirmed to be correct, the test machine can be switched on.

7. Turn on the power of the drive motor and confirm that the rotation direction of each drive device is consistent with the direction indicator.

8. Test run several times, 5 minutes each time, cut off the power supply, re-check according to the above requirements, and close the oil outlet control after confirming that it is correct The valve can be charged for trial operation.

9. Feed the material into the hopper and pass water to the spray pipe at the same time, open the observation cover on both sides of the machine, and adjust the speed of the reducer in time by checking the oil grinding on the orange surface to avoid unsatisfactory oil grinding or orange The surface of the orange is worn away. When the oil grinding is not ideal, it can be achieved by reducing the speed of the screw conveying shaft and speeding up the speed of the oil grinding roller. The operation method is to adjust the speed control handwheel on the transmission transmission reducer and the grinding oil transmission reducer; the orange surface is worn out Or when the whole fruit is grinded, it can be achieved by increasing the speed of the screw conveying shaft and reducing the speed of the oil grinding roller. The operation method is to adjust the speed control handwheel on the transmission transmission reducer and the grinding oil transmission reducer; When there are too many oranges (generally do not exceed the height of the hollow spiral), it will also affect the effect of oil grinding. This needs to be achieved by adjusting the hand wheel of the homogenizer reducer and controlling the feeding speed.

10. When there is too much oil-water mixture in the oil collecting hopper, open the oil outlet control valve to discharge the oil-water mixture.

11. After the oil grinding, let the machine idling for 5 minutes so that the spray water can take away as much oil as possible. Then cut off the power of each reducer and close the control valve at the water inlet of the spray pipe.

12. Put the oil-water mixture in the oil collecting hopper after the last.

13. When cleaning, open the observation covers on both sides of the machine and flush the inner wall of the machine with water pipes. Flush in the case of oil drive reducer power supply.

14. Add lubricant once every 100 hours of operation. The amount should be appropriate. If the grease is found to be dirty, discolored and deteriorated, the cause should be found immediately .

15. Frequently check whether the motor is overloaded and heats up. If any defects are found, please contact the maintenance personnel for repair.

16. Frequently check whether the burrs of the oil grinding roller and the hollow spiral are severely worn. If necessary, replace the burrs.

17. Always keep the inside and outside of the whole machine clean.

18. The lubricating oil of the transmission reducer must be changed regularly, and the dirty oil shall be drained when changing.

19. Lubricate the bearing parts regularly.