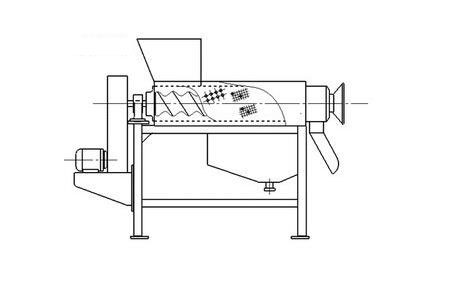

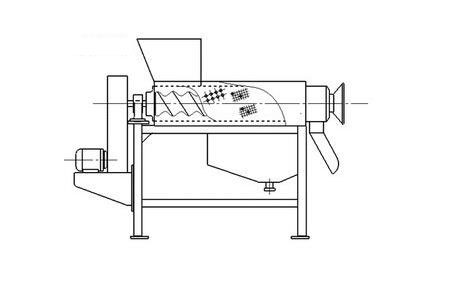

Installation operation and maintenance of screw juicer.

1.The machine must be installed horizontally and fixed with anchor bolts.

2.Tighten bolts on each part of the whole machine. Clean the inside and outside of the machine and keep it clean.

3.Before turning on the power supply of the drive motor, adjust the pressure head to make the annular gap larger. Operation method: pull up the brake pin and rotate it for 90o to fix the brake pin, and then rotate the handwheel counterclockwise to increase the gap between the pressure regulator head and the spiral cone. (Open the observation cover on the upper part of the rear support, and you can observe the gap change between the pressure regulating head and the spiral conical surface.)

4.Turn on the power supply of the drive motor and confirm that the rotating direction of the machine is consistent with the direction indicator.

5.Test run for 5 minutes. After confirming that everything is normal, the machine can feed normally.

6.feeding must be uniform, it is strictly prohibited to hard foreign matter into the hopper, so as not to damage the screen.

7.After feeding, turn the handwheel clockwise to gradually reduce the gap between the pressure regulating head and the spiral cone. After meeting the technological requirements, rotate the brake pin 90o to fix it in the groove of the handwheel bearing seat under the action of spring force, thus fixing the handwheel bearing seat.

8.When stopping the machine, directly cut off the power supply of the motor.

9.After working in each shift, the filter screen must be washed with water and brushes. If the juice with more fiber is finely filtered, it is necessary to wash the net once depending on the production situation, and wash all the machines with hot water after pressing.

10.often check whether the motor overload fever, found bad phenomenon, must contact the maintenance personnel for repair.

11.Check whether the drive belt is aged or cracked. If found, replace it in time.

12.Check whether the drive belt is loose or too tight. It is usually advisable to flip the belt with fingers for 90o. If it is too loose or too tight, adjust the adjusting bolts at the motor seat.

13.The bearings shall be replaced and filled with grease regularly, and the normal service temperature of the bearings shall be less than 80℃.