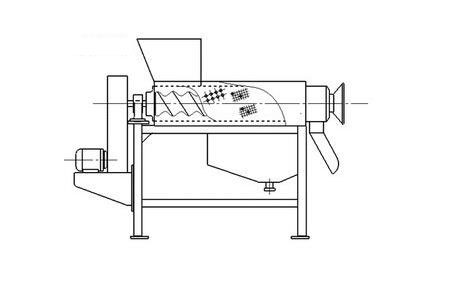

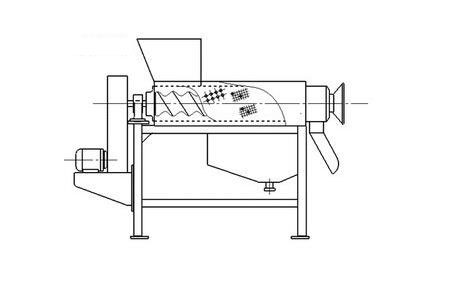

Main maintenance methods of spiral juicing machine:

1. the screw machine shall be started without load, that is, zhi shall be started when there is no material in du in the casing, and the screw machine can be fed after starting. when feeding is started at the beginning of dao, the feeding speed shall be gradually increased to reach the fixed conveying capacity. The feeding should be uniform, otherwise it is easy to cause blockage of conveying materials and damage to the whole machine due to excessive power plant.

2. In order to ensure that the screw machine starts without load, the conveyor should stop feeding before stopping, and stop running until the materials in the casing are completely lost

3. Hard bulk materials shall not be mixed into the conveyed materials, so as to avoid the damage of the screw machine caused by screw sticking.

4. Always check the working status of each part of the spiral juicing machine in use. Pay attention to whether the fasteners are loose. If the fastener is found to be loose, stop the machine immediately and tighten the screw to retighten it。

Safe use When the screw shaft rotates, due to the gravity of the material and the friction force between the material and the tank wall, the material can only move forward along the tank bottom of the conveyor under the push of the blade, as if the nut which can’t rotate moves in translation along the rotating screw. The movement of materials in the middle bearing depends on the thrust of the materials advancing behind.Therefore, the transportation of materials in the conveyor is a kind of sliding movement. In order to make the screw shaft in a favorable tension state, the driving device and the discharge port are usually placed at the same end of the conveyor, while the feed port is placed near the tail of the other end as far as possible. Rotating spiral blades push the materials to be transported,The force that makes the material not rotate with the blade of the spiral juicing machine is the weight of the material itself and the frictional resistance of the shell of the spiral juicing machine to the material. The blade surface types include solid surface type, belt surface type, blade surface type and so on.The screw shaft of spiral juicing machine has thrust bearing at the end of the material movement direction to give the axial reaction force to the screw along with the material. When the machine length is longer, the middle hanging bearing should be added.

Daily maintenance management spiral juicing machine in the use process, we must pay attention to the daily maintenance, so as to maximize the cooperation with the sand dryer, ensure the production capacity and efficiency, and extend the service life of the equipment.

(1) The bearing, gear and chain should be lubricated regularly.

(2) After the box feeder is out of service, the wear of spiral blades shall be checked, and repair welding shall be carried out in case of serious wear.

(3) The conveying capacity should not be overloaded, otherwise the material can not be discharged, which will cause the spiral shaft to bend and the box body to expand.

(4) When the transmission medium is high, attention should be paid to whether the expansion and contraction of the box is free and there is no stuck place, if there is a solution.

(5) When the conveyor is in operation and the noise is harsh, the cover should be opened for inspection and troubleshooting.