This equipment is a machine that uses a reducer to drive spiral rotation and push materials to achieve the purpose of conveying. It has a simple structure, a small cross-sectional area, and is convenient for enclosed transportation. It can be charged or unloaded at multiple points. Material and other advantages.

√Shell form: “o” type or “u” type;

√Spiral form: no axis, single axis or multiple axis;

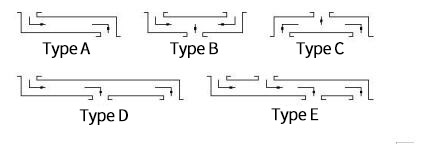

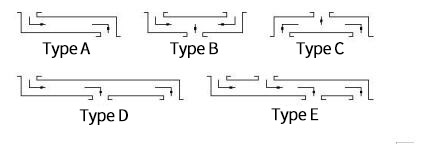

√According to the different flow directions of materials, you can choose the following five types of material feeding and discharging arrangements.

I. Overview

Screw conveyors and screw elevators use a transmission reducer to drive the spiral to move the material in a fixed shell to achieve the purpose of conveying or lifting. It can realize the horizontal conveying and inclined conveying of the material, and the vertical conveying of the material. For lifting, the shell forms of horizontal conveying and inclined conveying are “U” and “O”. The specific form can be selected according to the user’s different working conditions. The machine adopts foreign advanced technology for processing, and has the advantages of compact structure, low noise, convenient use, convenient closed conveying, lifting, multi-point feeding and multi-point unloading. It is an ideal equipment for conveying and lifting all kinds of powder, granular, small pieces and all kinds of fruits and vegetables. If the fruits and vegetables are transported vertically, an anti-shatter device can be designed for fruits and vegetables, and the damage rate is less than 1‰. This machine can also be designed according to user requirements.

2, the form of incoming and outgoing materials

According to different material flow directions, the above five types of material feeding and discharging arrangements can be used, and the inlet and outlet dimensions can be determined according to user requirements.

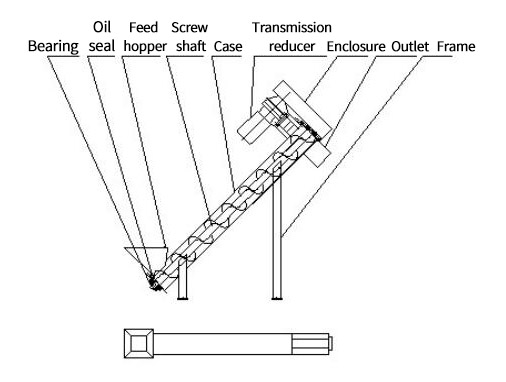

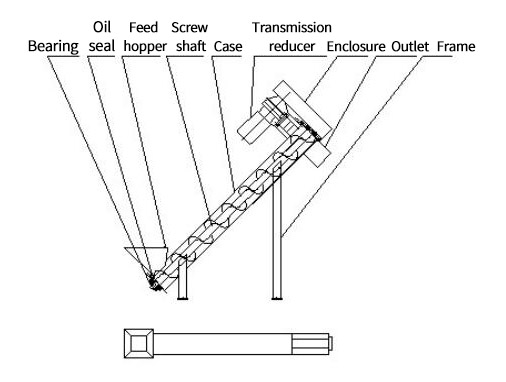

4, structure diagram and working principle

Diagram ①: O-shaped spiral elevator

Diagram ②: U-shaped screw conveyor

Screw conveyor and screw elevator are mainly composed of feed hopper, screw shaft, transmission reducer, discharge hopper, shell and other components. When working, the sprocket of the transmission reducer drives the screw shaft to rotate. After the material enters the shell, it moves to the discharge hopper under the thrust of the screw shaft to achieve the purpose of conveying or lifting.

5, installation, commissioning, use, operation, and maintenance

1. After the screw conveyor hoist is transported to the site, first fix the feet with expansion screws. In the case of a vertical screw hoist, the user is required to fix the upper part according to the specific situation of the workshop, and the fixed part is under the transmission reducer.

2. Before starting the machine, check whether the screws of each part are fastened.

3. Turn on the power supply of the transmission reducer, and confirm that the direction of rotation of the machine is consistent with the direction indicator.

4. Test run for 5 minutes, after confirming that the machine is normal, the feed can be normal.

5. Stones, screws, and tools are strictly prohibited from falling into the equipment to prevent them from falling into the next process.

6. After starting the machine, the conveying speed can be adjusted by the handwheel of the transmission reducer.

7. After shutting down, be sure to clean the inside and outside of the whole machine to keep it clean.

8. Regularly check the lubricating oil in the reducer and bearing parts.