Daily maintenance method of screw juicer:

1. Before use, clean the contact part between equipment and materials with cleaning solution.

2. When the pressing operation needs to be stopped near the end, do not stop the machine directly. Firstly, reduce the pressure of the hydraulic system, and push the crushed and dehydrated material residue away from the forced door at the end of the sieve barrel; Maybe the forced gate is raised by manual operation, and then the machine is allowed to run continuously for a period of time until the material residue in the screen bucket cannot be continuously discharged from the forced gate.Then stop the machine to clean the remaining material residue in the sieve bucket.

3. During the operation of the machine, excessive pressure should be avoided as far as possible, otherwise, the machine will suddenly stop or the screen bucket will break.

4. The oil temperature of hydraulic system shall not exceed 60℃. As the high pressure temperature of the hydraulic pump rises rapidly, it is suggested that the high pressure continuous operation of the hydraulic pump should not exceed 30 minutes. The temperature rise of bearings in transmission system shall not exceed room temperature 40℃.

5. During the operation of the machine, do not let sharp and hard objects and metal objects enter the machine body. They will damage the parts in the machine body and affect the normal operation of the machine, so they can be selected before material pressing.

6. If the machine is not used for a long time, all the material residues in the body must be cleaned with a water gun, and the rust-prone parts should be coated with grease for maintenance and placed in a ventilated and dry place.

7. The oil of hydraulic system should be kept clean. When refueling or changing oil, use 120 mesh filter screen to filter oil.

8. The bearings of the transmission system should be regularly injected with grease for maintenance; Lubricating oil should be regularly injected into the gear box for maintenance; Hydraulic oil tank should be filled with hydraulic oil regularly for maintenance.

Matters needing attention when using screw juicer:

When the screw juicer is used to dewater fruits and vegetables, due to the limitation of the gap between the sieve barrel and the sieve trough, a small amount of residue will be produced in the juicing process, which will make the juicing of fruits and vegetables cloudy. For example, even if the sieve gap is adjusted to be 0.2 meters smaller, the juice of juicy fruits such as apples and pears will still not be completely separated from the liquid, and the juice will be cloudy, thus failing to achieve the clear and visible effect.

Screw juicer squeezes miscellaneous materials such as kitchen waste and medical waste, but iron scraps and sharp and hard objects cannot enter the machine body, thus preventing the internal damage of the machine and affecting the normal operation.

Practicality of screw juicer: The separation of slag and liquid is fast, and the water content of manure residue after separation is between 40-55%, and the water content of residue and water content can be adjusted. Suitable for feeds with different ingredients (grass, concentrated feed, etc.). ), easy to transport, and its solid particles are suitable for fish feed and organic fertilizer raw materials.

Advanced nature of screw juicer: strong decontamination ability, no blockage and convenient cleaning. The solid content, chemical oxygen consumption, total oxygen consumption and nitrogen and phosphorus removal rate of the treated manure are between 70% and 95%, which is the reason of no odor.

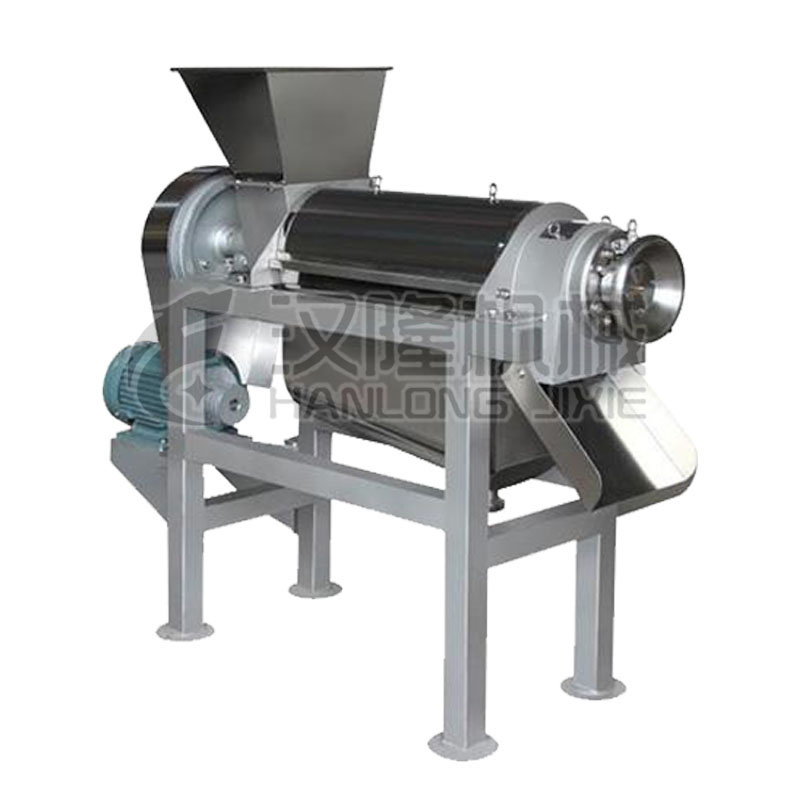

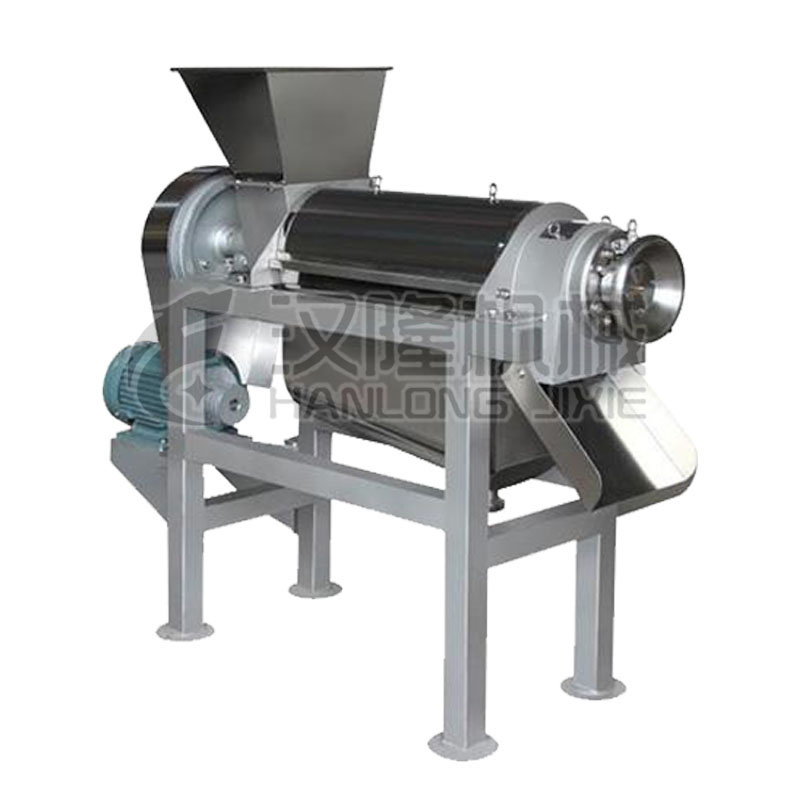

Durability of screw juicer: The frame, sieve frame, sieve frame and main body are made of stainless steel, and the stirring dragon is made of high hardness alloy. Corrosion-resistant, more durable than other similar machines. Similar screens are guaranteed for 3 years and have a long service life.

Screw juicer is used for solid-liquid separation of macroscopic world materials containing certain fibers or viscosity, such as grape pomace, ginger, spinach, rubber, Chinese herbal medicine, winter jujube and other fruits and vegetables containing certain fibers, and is also used for continuous juicing of seabuckthorn fruit with branches removed or a small number of branches, and its sieve holes are specially made according to the size of seabuckthorn seeds.

Working process of screw juicer:

The conveying screw pushes the material entering the material box to the pressing screw, and the liquid (fruit juice) contained in the material is extruded under the action of screen wall and cone resistance by reducing the pitch and increasing the shaft diameter of the pressing screw. The extruded liquid flows out of the sieve holes and is concentrated in the juice bucket.

Screw juicer is a complete set of mechanical equipment for preventing pollution in Geshan, which is composed of feed hopper, pressing screw, spiral steel pipe, slag discharge pipe and driving equipment. Grid residue or filter residue obtained by Geshan enters the spiral steel pipe from the feed hopper, and is extruded and formed under the action of the pressing screw, and dried. Gather the water-permeable filter screen squeezed in the raw material into the water receiving tank and discharge it through the drain pipe.The raw materials are discharged through the slag discharge pipe after being reduced, which can greatly reduce the net weight and volume of dirt such as grid slag. Screw juicer is composed of drainage pipe area, feeding area, screw transportation area and feeding area. Grid slag enters the material area, and is compacted in the compaction area according to the screw juicer. After that, grid slag is discharged, and wastewater is injected into the water collecting pipe from grid bars.