Welcome To Visit Jiangsu Hanlong Machinery Manufacturing Co., Ltd. Website!

Years of focus fruit and vegetable processingProvide solution design, equipment selection, one-stop service

Consultation Hotline:+86-18961025500

Welcome To Visit Jiangsu Hanlong Machinery Manufacturing Co., Ltd. Website!

Consultation Hotline:+86-18961025500

Hot search:Belt juicer and Industrial juice extractor

Technological process of working industrial fruit juicer machine

Juice yield of working industrial fruit juicer machine

Common models of industrial fruit juicer machine

Fruit → grading and weighing → fruit pond → hydraulic transportation → cleaning → sorting → spraying → crushing → enzyme treatment → juice pressing → pasteurization → degumming → ultrafiltration → evaporation and concentration → pasteurization → aseptic filling.

The main equipment for fruit juice production mainly consists of three parts:

1. Juice,

2. Degumming treatment+ultrafiltration,

3. Concentrate.

The key equipment in juice production is juicing equipment. The so-called juicing is the process of pushing an object (extrusion surface) and extruding the liquid and gas substances in the mixture composed of solid, liquid and gas substances from a limited space (extrusion chamber). If the extrusion equipment is reasonable, only gas and liquid substances can be extruded from the extrusion chamber.While leaving the solid matter in the extrusion chamber.

The factors affecting juice yield are:

1. Extrusion force: Within a certain pressure range, the juice yield is directly proportional to the extrusion force. But this range is critical.

2. Crushing degree of pulp and mud

3. Thickness of extruded layer

4. Pre-discharge juice

5. Juice additives, with or without additives, affect the juice yield up to 11.7%.

Intermittent: room juicer, package juicer,

Continuous: screw juicer, belt juicer.

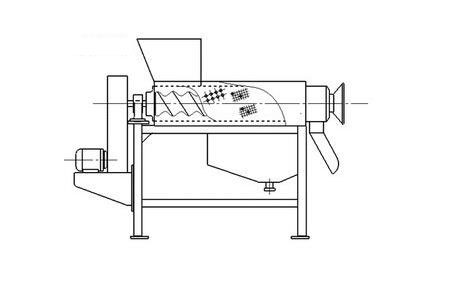

1. Screw juicer, which is widely used in China, has simple structure, few faults and high production efficiency. But the juice yield is low, which is 40-60% in most cases, and the turbidity is more than 3%.

2. Belt juicer, with continuous operation and high working efficiency, is suitable for mass production. The juice yield is high, about 78%. Belt juicer is the most advanced juicing equipment for fruit juice production at home and abroad.

Because there are many turbid substances in the initial juice, which affect the concentration of juice and the final product quality, it is necessary to purify the initial juice, mainly using various separation ultrafiltration equipment, and clarifying the separation to improve the separation factor and efficiency. Concentrate, which is to purify the fruit juice under high vacuum and 60-65℃,Evaporate most of the water in the fruit juice, reduce the volume to about 1/6 of the original volume, and increase the content of soluble solids from about 12% to 72%. Convenient for transportation and storage. At present, the prices of various concentrated fruit juices in the domestic market are generally around 10,000-12,000 yuan.

Contact Us

Factory address: No. 16 Ruijiang Road,Products

Juicing equipmentPulping equipmentDeseed and nuclear equipmentCrushing equipmentGrading equipmentCoconut processing equipmentPomegranate processing equipmentSoftening equipmentMore+Hanlong News

Company newsIndustry newsCommon problemSolution

Apple、PearTomatoMango、PineappleCitrus、Orange、LemonCarrotCoconutApricot、Plum、PeachBlueberry、Raspberry、StrawberryHanlong Machinery All Rights Reserved