The equipment uses food-grade plastic scrapers as the conveying carrier, which is suitable for the lifting and conveying of various fruits and vegetables in the food industry.

I. Overview

The elevator adopts plastic mesh belt baffle or woven polypropylene belt baffle as the carrier, which is suitable for the lifting and conveying of various fruits and vegetables in the food industry. The machine can design spray and water collection devices according to customer requirements. The machine uses a transmission motor to drive the active shaft. There are sprockets at both ends of the shaft to drive the conveying chain plate to rotate, so that the material can be conveyed or lifted. It can realize both horizontal conveying and inclined lifting conveying. When inclined conveying The lifting angle is generally not greater than 45°. The specific form can be selected according to the user’s different working conditions. The machine is processed by foreign advanced technology and has the advantages of compact structure, low noise, convenient use, and convenient for open transportation and lifting. It is an ideal equipment for conveying and lifting all kinds of fruits and vegetables.

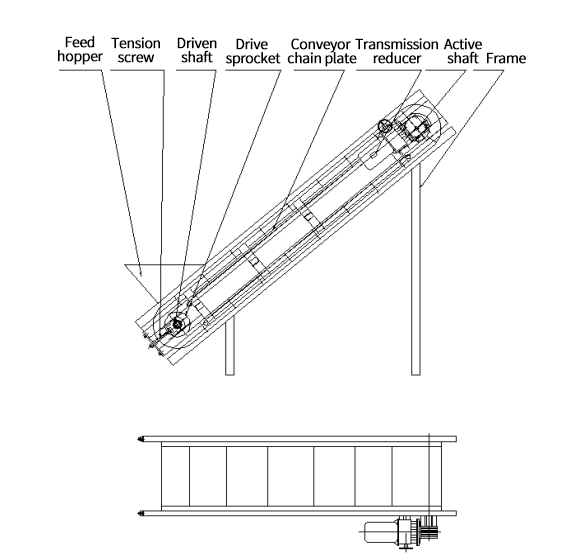

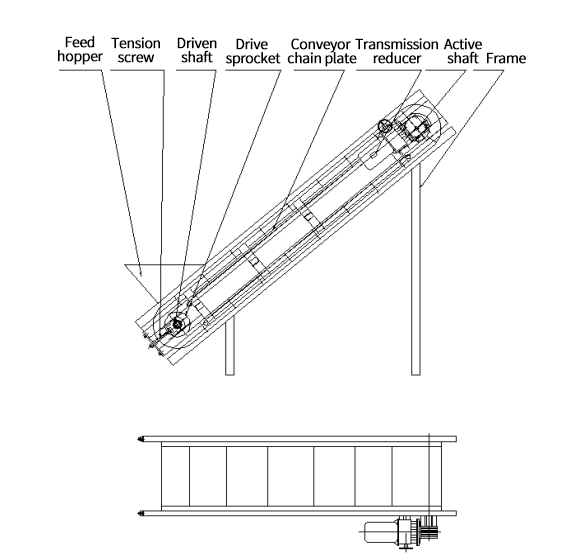

2. Structural features and working principle

The hoist is composed of a frame, a feeding hopper, a tension screw, a conveyor chain plate, a driving shaft, a driven shaft, a transmission sprocket, a transmission reducer and other components.

Working principle: Fruits are fed into the feeding hopper of the machine, and the plastic chain plate conveyor belt is driven by the drive sprocket on the drive shaft to transport and lift the fruits to the next process. The machine frame is made of all stainless steel materials, and can be made of various profiles according to user requirements, and can also be added with sprinkler pipes and water collection tanks.

3, technical parameters

Effective width: 300-1200mm

Lifting angle: ≤45°

Single drive limit length: 1000-10000mm

Conveying speed: maximum 32m/min (adjustable)

Motor power: 0.18 Kw /0.37 Kw /0.55 Kw /0.75 Kw /1.1 Kw /1.5 Kw /2.2Kw

4, Installation adjustment, maintenance and maintenance

1. The installation must be firm and the rack must be level.

2. Before starting the machine, check whether the screws in each part are fastened.

3. Before the machine is used, grease should be added once to each bearing and stepless transmission, and then once every six months.

4. Turn on the power, start the transmission reducer, check whether the plastic chain plate mesh belt is tightened, if there is looseness, adjust the tensioning screw to tighten the plastic chain plate mesh belt.

5. Stones, screws, and tools are strictly prohibited from falling into the equipment to prevent them from falling into the next process.

6. Test run several times, each time no more than 20 minutes, cut off the power supply, re-check according to the above requirements, and only after confirming that it is correct, can the feed test run.

7. Lubricate all parts of the machine regularly.

8. After shutting down, be sure to clean the inside and outside of the whole machine to keep it clean.